Evaluate the Bending Angle: Not all angles are feasible with a few metals, as they can crack if bent as well far.

While in the 13th century, “presse” was used for a noun which means “to crush or crowd.” Later on, within the 14th century, “press” was accustomed to consult with a device for pressing clothing or squeezing juice from grapes and olives.

The body of your press brake serves as the muse to the installation of hydraulic elements, While using the oil tank integrated into your stamping frame.

The Tool Setup Optimizer possibility checks which sections you may need the same tools for And the way the tool stations could be finest put together. This enables you to bend the maximum amount of elements with only one tool set up.

At a minimal, the smallest bend radius need to be not less than equal to the sheet thickness to avoid fractures or distortions within the metal portion.

To establish a dependable terminology for this handbook, Allow’s look at The important thing components of a contemporary press brake:

The electrical Command system of a modern press brake comprises three major parts: an electrical Regulate cupboard, a numerical Management (CNC) system console, and an operator station.

As press brake technological know-how advancements, suppliers are producing more and more sophisticated seal designs to satisfy the demands of better pressures, a lot quicker cycle times, plus more complex bending operations in contemporary sheet metal fabrication.

The key reason why powering This is often, that if there is rapid substance following the compressed material, you must change the flat product.

What is the greatest sheet metal bending method? Figuring out the top sheet metal bending method might be tough, as Every method is designed to provide certain applications and deliver distinct styles. By way of example, air bending is multipurpose and suitable for different resources, which makes it perfect for common purposes.

The central Manage block combines the three Handle blocks into just one, and is principally Utilized in specialised structures for Management applications. The Manage click here block and the connection concerning the two hydraulic cylinders has to be inside of a symmetrical arrangement.

With this technique, all sides of the sting may be formed at the same time, significantly boosting productivity. Moreover, the risk of surface cracking during the deformed space is negligible.

To be a rule of thumb, the upper the tonnage, the thicker metal that can be worked. Commonly, hydraulic presses are utilized to accomplish very substantial quantities of drive, and pneumatic and servo electric presses offer lesser amounts of pressure.

Appropriate variety and typical calibration of press brake gauges are essential for sustaining producing quality requirements and making sure steady element manufacturing in sheet metal fabrication processes.

Amanda Bearse Then & Now!

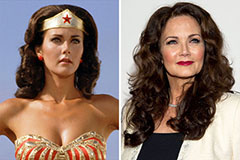

Amanda Bearse Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!